Polymer Preparation Solutions From ProMinent

Polymer Preparation Solutions From ProMinent

Systems for Preparation, Storage and Dosing of Dry and Emulsion Polymers

Take Advantage of the Benefits ProMinent Experience Brings to the Table with Our Comprehensive Product Offering

From Small Economical Units to Large 100+ kg / hour Bulk Preparation Systems We Can Handle the Full Range

Contact ProMinent for the Complete Engineered Solution

ProMinent Dry Polymer Preparation Systems ProMinent PolyRex - Polymer Demand up to 50 kg / hour ProMinent Ultromat - Continuous Economical Polymer Preparation

ProMinent PolyRex - Polymer Demand up to 50 kg / hour

ProMinent PolyRex - Polymer Demand up to 50 kg / hour Complete Polymer Preparation Systems

Great for 25 kg and Bulk Bags Completely Enclosed Polymer Wetting Area – Eliminate Dust Hygenic Bag Clamp To Eliminate Bulk Bag Spillage Batch Polymer Preparation Main Controls with PLC and HMI Polymer Flow up to 11,500 litres / hour as standard Options to go to over 120 kg / hour polymer

ProMinent Ultromat - Continuous Economical Polymer Preparation

ProMinent Ultromat - Continuous Economical Polymer Preparation Continuous Polymer Preparation 3 Tank design reduces overall footprint Up to 8,000 litres / hour polymer production Up to 80 kg/hour dry polymer Can also be fit for emulsion

Polymer Rental Program

ProMinent Offers Weekly / Monthly and Quarterly Options for System Rentals

If you have a short term requirement for a polymer preparation system the PolyRex 2.0 may be the right unit for you.

Short Term Polymer Trial Pending or Potential Emergency Requirements Short Term Dewatering Applications Existing System Offline for Maintenance

Emulsion / Liquid Polymer Systems ProMinent DulcoBlend Mixing Chamber Design Industrial Emulsion Systems

ProMinent DulcoBlend

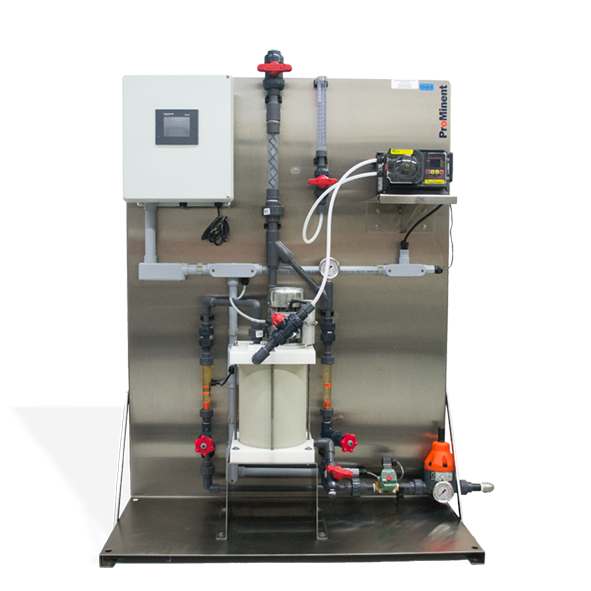

ProMinent DulcoBlend Emulsion Preparation System for Liquid Polymers

Up to 2.74 GPH Emulsion Polymer Water Pressures to 100 psig Primary Dilution to 300 GPH

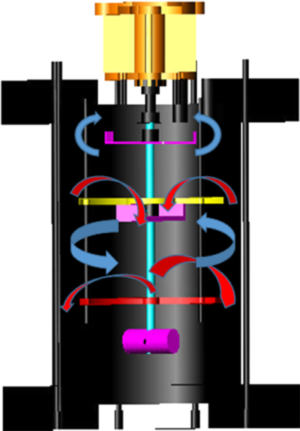

Mixing Chamber Design

Mixing Chamber Design 3 Step mixing Process

The unique design of the DucloBlend mixing chamber provides guaranteed activation with a gradual mixing profile. Starting with high energy mixing to eliminate agglomeration, using a vortex zone to eliminate short circuiting and a gentle mixing zone to allow for maturation prior to discharge to your process. The unit will reduce polymer use 10-15% over standard inline mixers saving costs on polymers.

Industrial Emulsion Systems

Industrial Emulsion Systems DulcoBlend I – Industrial Emulsion System

Only system with ABSA and TSSA CRN Approval for high pressure and temperature High Temperatures – 93 C CRN for piping designs up to 200 psig Proven 3 chamber mixing process. Overall Reduction in Polymer Consumption

to top